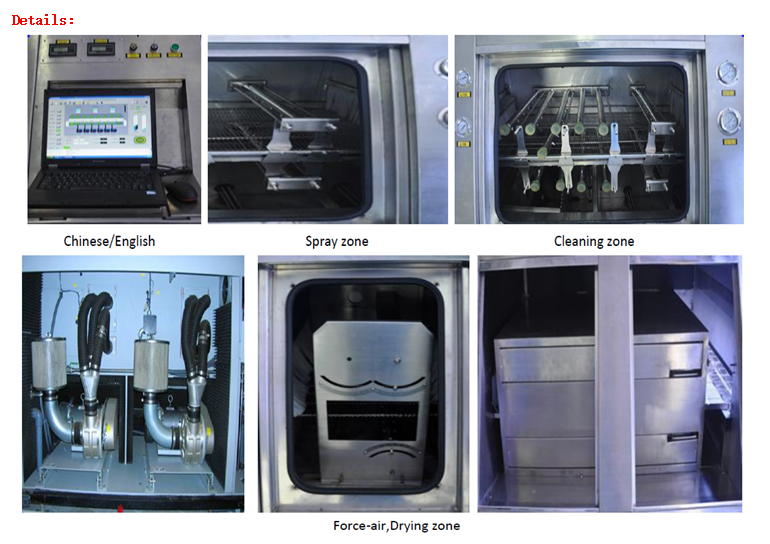

10. Total SUS304 structure, Acid and Alkali corrosion resistance.

Specification:

|

Item |

YS-6100 |

|

Conveyor net width |

600mm |

|

Conveyor net speed |

100~1500mm/min, suggest 300~400mm/min |

|

Conveyor height |

900±50mm |

|

PCB conveyor direction |

From Left to Right |

|

PCB width |

60~600mm |

|

PCB clean height |

0~100mm |

|

Clean tank |

300L |

|

Rinse tank |

300L |

|

DI water consumption |

1~1.5m³/H |

|

Exhausted air |

12m³/H |

|

Control |

PC+PLC |

|

Power/air supply |

380VAC,3P,50/60HZ,70KW/0.5Mpa |

|

Resistivity range |

0~18MΩ |

|

Machine size |

4350(L)x1530(W)X1620(H) mm |

|

Machine weight |

1500KG |

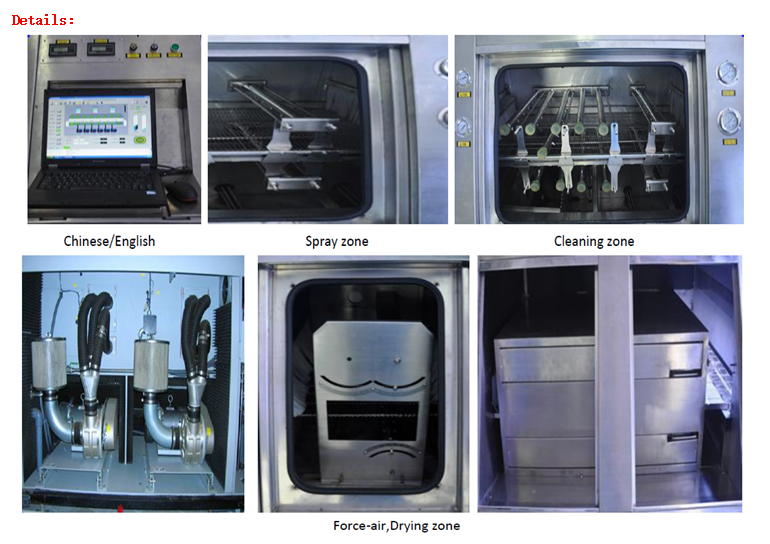

10. Total SUS304 structure, Acid and Alkali corrosion resistance.

Specification:

|

Item |

YS-6100 |

|

Conveyor net width |

600mm |

|

Conveyor net speed |

100~1500mm/min, suggest 300~400mm/min |

|

Conveyor height |

900±50mm |

|

PCB conveyor direction |

From Left to Right |

|

PCB width |

60~600mm |

|

PCB clean height |

0~100mm |

|

Clean tank |

300L |

|

Rinse tank |

300L |

|

DI water consumption |

1~1.5m³/H |

|

Exhausted air |

12m³/H |

|

Control |

PC+PLC |

|

Power/air supply |

380VAC,3P,50/60HZ,70KW/0.5Mpa |

|

Resistivity range |

0~18MΩ |

|

Machine size |

4350(L)x1530(W)X1620(H) mm |

|

Machine weight |

1500KG |