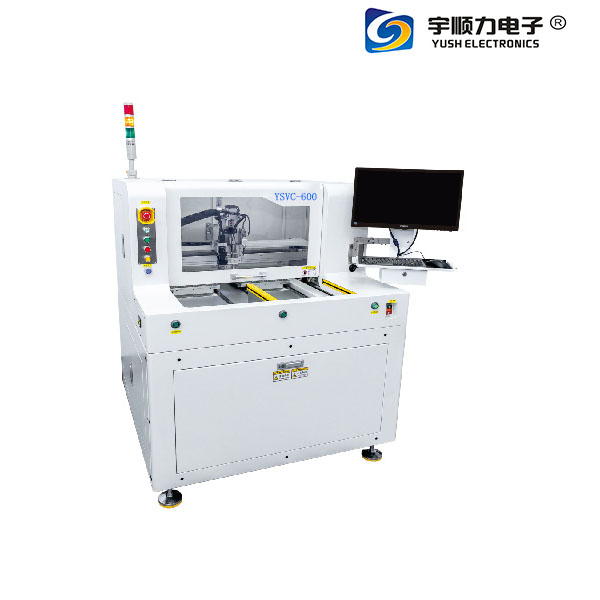

Basic parameter Specifications:

1. Single side working size: 290mm X 350mm

3. X-Y AC Servo speed: 0-1000mm/sec

5.X-Y repetition accuracy: ±0.01mm

7. CCD camera calibration accuracy: ±0.01mm

9. NSK spindle speed: Max.60,000rpm

11. PCB board cutting thickness: 0.2mm-6.0mm

13. Dust collection cabinet size: 640mm×785mm×1760mm(D×W×H)

15. Weight of main engine + dust collector: 800 KG

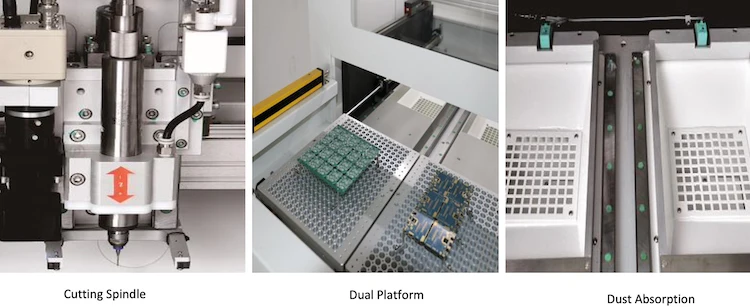

On the dust features: milling cutter board machine is also called curve board machine, using electrostatic brush seal cutting point. Independent for single cut point vacuuming. Greatly improve the effect of vacuuming.

Windows OPERATION INTERFACE friendly switching between Chinese AND English, ILLUSTRATED Windows operation interface, editing program is simple, can quickly complete multi-point programs.

Software sets milling cutter segmentation function, automatic cutting compensation, prolong the service life of milling cutter, reduce the cost.

Basic parameter Specifications:

1. Single side working size: 290mm X 350mm

3. X-Y AC Servo speed: 0-1000mm/sec

5.X-Y repetition accuracy: ±0.01mm

7. CCD camera calibration accuracy: ±0.01mm

9. NSK spindle speed: Max.60,000rpm

11. PCB board cutting thickness: 0.2mm-6.0mm

13. Dust collection cabinet size: 640mm×785mm×1760mm(D×W×H)

15. Weight of main engine + dust collector: 800 KG

On the dust features: milling cutter board machine is also called curve board machine, using electrostatic brush seal cutting point. Independent for single cut point vacuuming. Greatly improve the effect of vacuuming.

Windows OPERATION INTERFACE friendly switching between Chinese AND English, ILLUSTRATED Windows operation interface, editing program is simple, can quickly complete multi-point programs.

Software sets milling cutter segmentation function, automatic cutting compensation, prolong the service life of milling cutter, reduce the cost.