Device overview

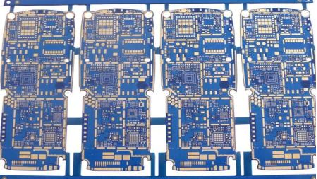

YSL-660 series automatic PCBA board cleaning machine; is an on-line automatic PCBA board special cleaning machine, suitable for traditional board washing water, without manual contact with cleaning agent, the equipment combines PCBA board transmission technology with brush cleaning technology Combined, multiple brushes in all directions, front, back, left and right, cleaning without dead ends, to ensure that the PCBA board meets the cleanliness requirements. It is suitable for cleaning the welding surface of single-sided PCBA board, and will not wet the front components.

Machine Features

1. The machine has a unique body structure, stable performance and the highest cleaning effect in the industry.

2. It is specially used for the cleaning of tin beads, flux traces and scratches.

3. Imported brown brush, anti-static brush, will not generate static electricity and will not hurt the PCBA board.

4. It is suitable for PCB boards with board edges, (the board edge distance is at least 1.5mm), and the PCBA board adapts to the width range.

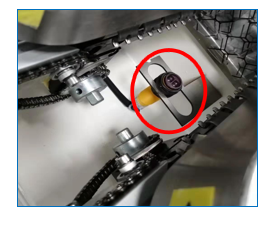

5. Thickened shrapnel claw ensures that the PCBA board will not shift during transportation.

6. Cleaning agent automatic coating system: ensure that the welding surface of the PCBA board can be evenly coated with washing water without affecting the surface of other parts.

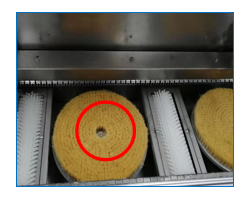

7. Disc brush + two rollers: ensure that the PCBA board is cleaned in place in all directions without dead ends.

8. The cleaning brush height and speed (stepless speed change) can be adjusted to adapt to different levels of cleaning needs.

9. The waste generated by the work is automatically gathered in the filter box at the lower part of the machine, which is convenient for cleaning.

10. Driven by high-quality electronic speed-regulating motor, the motor speed is steplessly adjustable and durable.

11. Powered by 220 volts. Easy to use.

12. Adopt brand electrical appliances and control system to ensure the reliability and stability of the control system.

13. Adopt modular control.

PCB/PCBA

Structure and function

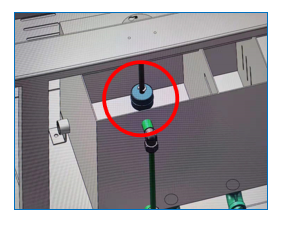

1. Equipment structure: including feeding and connecting mechanism, transportation mechanism, brush cleaning system, circulating filter system, air drying system, PLC program controller, and other automatic control systems. Each system is an independent modular design, easy to operate and easy to maintain.

2. The whole machine is automatically controlled by PLC, with complete functions and two operating modes, automatic and manual. The automatic mode (economy operation mode) can significantly reduce the consumption of cleaning agent and electric energy.

3. The disc brush and the roller brush simultaneously clean the bottom of the PCB A board in all directions, front, back, left and right, and there is no dead angle for cleaning;

4. Cleaning module Equipped with a completely closed three-stage automatic circulation filtration system, which continuously filters and cleans the stains, so that the cleaning liquid is always maintained at a high level of activity, and the cleaning liquid is recycled.

5. The cleaning liquid tank is equipped with low liquid level alarm and over-limit liquid level alarm functions.

6. The air-drying device acts on the cleaned PCB A board through the fan to make the surface dry quickly.

7. The motors of the wet cleaning module and the dry cleaning module are independent, and the speed can be adjusted independently. The height can be adjusted independently.

| Model | YSL-660 | YSL-660N |

| Maximum size of PCBA board: | 350mm(L) x 350mm(W) | 550mm(L) x550mm(W) |

| External dimensions: | L1880*W870*H980±2mm | L2150*W970*H980±2mm |

| Coating Roller Size: | φ100mm | φ100mm |

| Disc brush size: | φ350mm | φ550mm |

| Spindle speed: | 0-500 rpm (adjustable) | 0-500 rpm (adjustable) |

| Operating Voltage: | 220V/50HZ | 220V/50HZ |

| Total power: | 1(KW) | 2.2(KW) |

| Transmission speed: | 0.05~1.8m/min(stepless speed change) | 0.05~1.8m/min(stepless speed change) |

Structure and function

Primary Wet Cleaning Module

It consists of two sets of abrasive brushes and two sets of spray pipes. The PCB board is brushed by reverse rotation, and the cleaning liquid is returned to the circulation system.

Secondary dry cleaning module

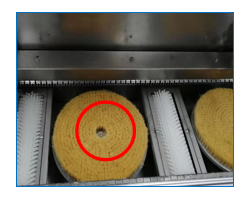

Contains a set of disc brown brushes that rotate in reverse to clean the PCBA board.

Three-stage wet cleaning module

It consists of a set of roller abrasive brushes and a set of spray pipelines. The PCBA board is brushed by reverse rotation, and the cleaning liquid is returned to the circulation system.

Four-stage dry cleaning module

Contains a set of disc brown brushes that rotate in a positive direction to clean the PCBA board.

Machine structure and features

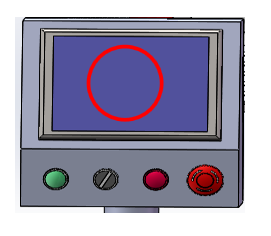

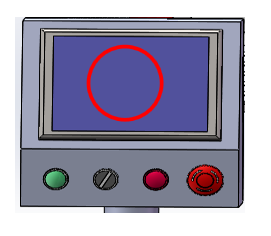

1.Touch screen control, the machine has the function of automatically adding and draining liquid medicine, and displaying the liquid level in real time

2.Liquid level control system: When the liquid level in the liquid storage tank drops to the low level warning line, the liquid level controller will send an alarm signal to prompt manual replenishment.

3.Imported anti-static brushes are used, which are wear-resistant, have a long service life and reduce maintenance costs.

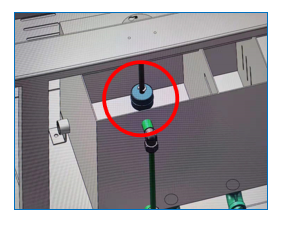

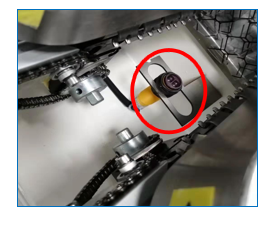

4.Precise induction, more energy-saving and efficient, and reduce the cost of use.

5.Independent air outlets on both sides will not cause environmental pollution, more environmentally friendly and adjustable.

Cleaning agent circulation system

1. Cleaning tank

2. Liquid storage tank

3. Primary filter

4. Sedimentation tank

5. Reservoir

6. Circulating pump

Control System

Manual operation mode

Each system function can be completed manually one by one

Fully automatic operation mode

1. When there is no PCBA board in the machine, the system will judge. At this time, the brush will be cleaned and the water pump will enter the stop state.

2. The cleaning fluid circulation system enters a fully closed state

cleaning process

| Project | Craft name | Cleaning introduction | Cleaning speed | Cleaning method | Cleaning box | Note |

| 1 | Primary cleaning | Wet Type | Adjustable | Roller brush (black) | Custom made | Anti-static material |

| 2 | Secondary dry cleaning | Dry type | Adjustable | Disc Brush (Black) | Custom made | Anti-static material |

| 3 | Three-stage cleaning | Wet Type | Adjustable | Roller brush (black) | Custom made | Anti-static material |

| 4 | Level 4 Dry Cleaning | Dry type | Adjustable | Disc Brush (Black) | Custom made | Anti-static material |

Device overview

YSL-660 series automatic PCBA board cleaning machine; is an on-line automatic PCBA board special cleaning machine, suitable for traditional board washing water, without manual contact with cleaning agent, the equipment combines PCBA board transmission technology with brush cleaning technology Combined, multiple brushes in all directions, front, back, left and right, cleaning without dead ends, to ensure that the PCBA board meets the cleanliness requirements. It is suitable for cleaning the welding surface of single-sided PCBA board, and will not wet the front components.

Machine Features

1. The machine has a unique body structure, stable performance and the highest cleaning effect in the industry.

2. It is specially used for the cleaning of tin beads, flux traces and scratches.

3. Imported brown brush, anti-static brush, will not generate static electricity and will not hurt the PCBA board.

4. It is suitable for PCB boards with board edges, (the board edge distance is at least 1.5mm), and the PCBA board adapts to the width range.

5. Thickened shrapnel claw ensures that the PCBA board will not shift during transportation.

6. Cleaning agent automatic coating system: ensure that the welding surface of the PCBA board can be evenly coated with washing water without affecting the surface of other parts.

7. Disc brush + two rollers: ensure that the PCBA board is cleaned in place in all directions without dead ends.

8. The cleaning brush height and speed (stepless speed change) can be adjusted to adapt to different levels of cleaning needs.

9. The waste generated by the work is automatically gathered in the filter box at the lower part of the machine, which is convenient for cleaning.

10. Driven by high-quality electronic speed-regulating motor, the motor speed is steplessly adjustable and durable.

11. Powered by 220 volts. Easy to use.

12. Adopt brand electrical appliances and control system to ensure the reliability and stability of the control system.

13. Adopt modular control.

PCB/PCBA

Structure and function

1. Equipment structure: including feeding and connecting mechanism, transportation mechanism, brush cleaning system, circulating filter system, air drying system, PLC program controller, and other automatic control systems. Each system is an independent modular design, easy to operate and easy to maintain.

2. The whole machine is automatically controlled by PLC, with complete functions and two operating modes, automatic and manual. The automatic mode (economy operation mode) can significantly reduce the consumption of cleaning agent and electric energy.

3. The disc brush and the roller brush simultaneously clean the bottom of the PCB A board in all directions, front, back, left and right, and there is no dead angle for cleaning;

4. Cleaning module Equipped with a completely closed three-stage automatic circulation filtration system, which continuously filters and cleans the stains, so that the cleaning liquid is always maintained at a high level of activity, and the cleaning liquid is recycled.

5. The cleaning liquid tank is equipped with low liquid level alarm and over-limit liquid level alarm functions.

6. The air-drying device acts on the cleaned PCB A board through the fan to make the surface dry quickly.

7. The motors of the wet cleaning module and the dry cleaning module are independent, and the speed can be adjusted independently. The height can be adjusted independently.

| Model | YSL-660 | YSL-660N |

| Maximum size of PCBA board: | 350mm(L) x 350mm(W) | 550mm(L) x550mm(W) |

| External dimensions: | L1880*W870*H980±2mm | L2150*W970*H980±2mm |

| Coating Roller Size: | φ100mm | φ100mm |

| Disc brush size: | φ350mm | φ550mm |

| Spindle speed: | 0-500 rpm (adjustable) | 0-500 rpm (adjustable) |

| Operating Voltage: | 220V/50HZ | 220V/50HZ |

| Total power: | 1(KW) | 2.2(KW) |

| Transmission speed: | 0.05~1.8m/min(stepless speed change) | 0.05~1.8m/min(stepless speed change) |

Structure and function

Primary Wet Cleaning Module

It consists of two sets of abrasive brushes and two sets of spray pipes. The PCB board is brushed by reverse rotation, and the cleaning liquid is returned to the circulation system.

Secondary dry cleaning module

Contains a set of disc brown brushes that rotate in reverse to clean the PCBA board.

Three-stage wet cleaning module

It consists of a set of roller abrasive brushes and a set of spray pipelines. The PCBA board is brushed by reverse rotation, and the cleaning liquid is returned to the circulation system.

Four-stage dry cleaning module

Contains a set of disc brown brushes that rotate in a positive direction to clean the PCBA board.

Machine structure and features

1.Touch screen control, the machine has the function of automatically adding and draining liquid medicine, and displaying the liquid level in real time

2.Liquid level control system: When the liquid level in the liquid storage tank drops to the low level warning line, the liquid level controller will send an alarm signal to prompt manual replenishment.

3.Imported anti-static brushes are used, which are wear-resistant, have a long service life and reduce maintenance costs.

4.Precise induction, more energy-saving and efficient, and reduce the cost of use.

5.Independent air outlets on both sides will not cause environmental pollution, more environmentally friendly and adjustable.

Cleaning agent circulation system

1. Cleaning tank

2. Liquid storage tank

3. Primary filter

4. Sedimentation tank

5. Reservoir

6. Circulating pump

Control System

Manual operation mode

Each system function can be completed manually one by one

Fully automatic operation mode

1. When there is no PCBA board in the machine, the system will judge. At this time, the brush will be cleaned and the water pump will enter the stop state.

2. The cleaning fluid circulation system enters a fully closed state

cleaning process

| Project | Craft name | Cleaning introduction | Cleaning speed | Cleaning method | Cleaning box | Note |

| 1 | Primary cleaning | Wet Type | Adjustable | Roller brush (black) | Custom made | Anti-static material |

| 2 | Secondary dry cleaning | Dry type | Adjustable | Disc Brush (Black) | Custom made | Anti-static material |

| 3 | Three-stage cleaning | Wet Type | Adjustable | Roller brush (black) | Custom made | Anti-static material |

| 4 | Level 4 Dry Cleaning | Dry type | Adjustable | Disc Brush (Black) | Custom made | Anti-static material |