Features:

1.750 plate splitting machine adopts six groups of cutting tools to cut step by step to reduce the shear stress to the minimum, and is equipped with deformation control device, the edge of the segmented substrate is smooth and smooth, the surface is very smooth, no twisting or warping, yes

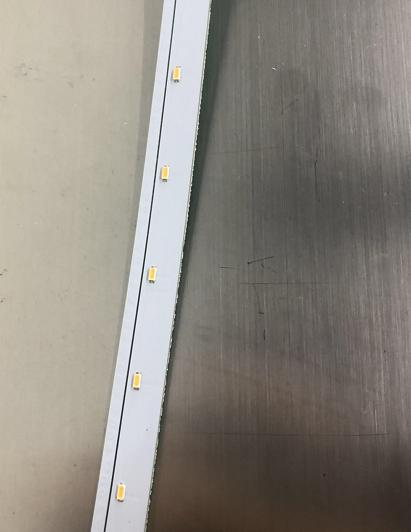

About 0.6mm ultra-thin aluminum substrate slitting can still perfectly control its deformation in two wires, meet the glass

The strict requirement of deformation degree in pipe process

2. Because of multiple cutting, the cutting process is very smooth, greatly improving the positioning ability of V-CUT slot, even if the V-CUT slot is very shallow circuit board, there will be no V-CUT slot from the guide knife jump out of the situation, to avoid defective products.

3. All cutting blades are calibrated with an excited dual-frequency laser interferometer to ensure that the rear blade can be cut in the slot of the front blade

Continue cutting exactly. Tip beat no more than 0.02mm, to ensure perfect cutting quality.

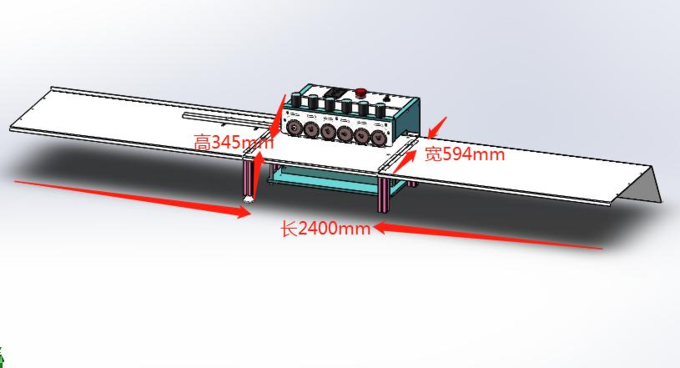

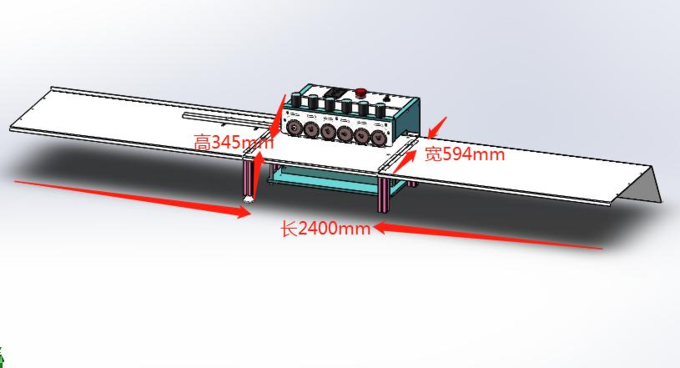

4. Stainless steel platform with laser calibration positioning function (1.2m or 2.4m optional)

Application field

The YSL-750 is used in:

750 plate machine adopts six groups of cutting tools to cut step by step, the shear stress is reduced to the minimum, and the deformation control device is configured, the edge of the segmented substrate is smooth, the surface is very flat, no twisting or warping, the ultra-thin aluminum substrate cutting about 0.6mm can still perfectly control its deformation in two wires, to meet the glass tube process on the deformation of the harsh requirements.

Because of multiple cuts, the cutting process is very smooth, greatly improve the positioning ability of V-CUT slot, even if the V-CUT slot is very shallow circuit board, there will be no V-CUT slot from the guide knife jump out of the situation, avoid bad

a. Mainly used in electronic, electrical, lighting, medical, automobile new energy, automobile and other electronic technology industries;

Defective PCB board

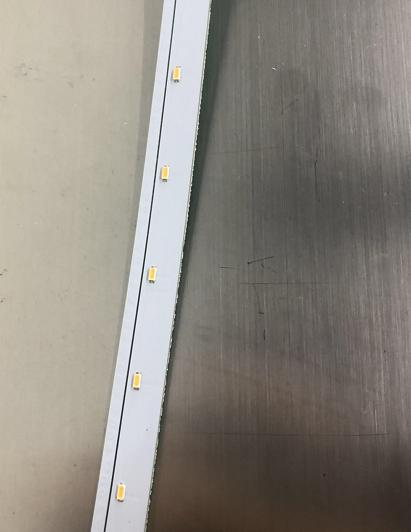

Machine sub-board after PCB board

Equipment parameter

| Machine specification | 490mm*400mm*350mm |

| Plat size | 1200*450*350mm/2400*450*35mm |

| Maximum splitter length | Unlimited |

| Split-plate velocity | 80, 120, 200, 400mm/s |

| Power | 60W |

| Tool material | SKD61 High speed steel |

| Plate thickness | 0.2-5mm |

| Machine weight | 1.2M—65KG;2.4M—75KG |

| Power supply | 230V/50Hz(110V/60Hz) |

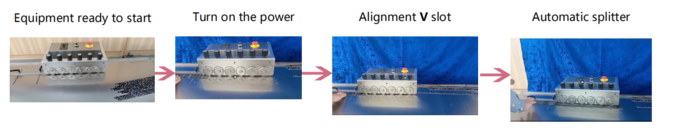

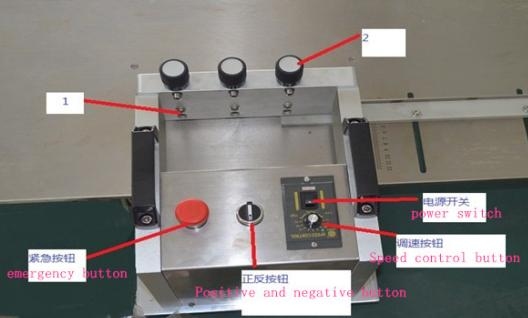

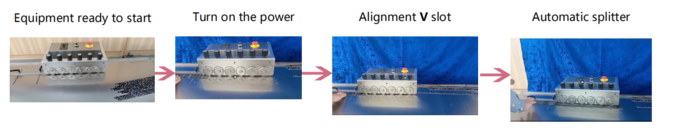

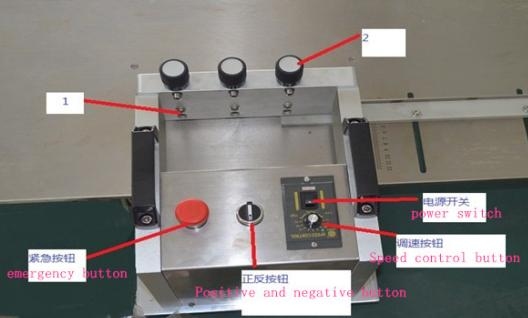

Board operation procedure

value

A Cost saving

Maximum plate cutting length: unlimited, maximum plate thickness :0.2-5mm, the cutting force of the blade is small, and the use of high-speed steel materials imported from Germany, the blade durability is greatly improved, the blade life can reach more than one year when dividing the aluminum substrate. Applicable circuit plate wide range, save manpower, greatly improve the product efficiency.

B High equipment efficiency

X and Y axis can be adjusted freely to improve the cutting accuracy to the highest. The speed of the sub-board can reach 80, 120, 200, 400mm/ s. The upper and lower round knife can be adjusted accurately, simple operation, fast speed.

C Quality is guaranteed

All cutting blades are calibrated with an excited dual-frequency laser interferometer to ensure that the rear cutter can accurately continue cutting in the slot where the front cutter cut. Tip beat no more than 0.02mm, to ensure perfect cutting quality.

Equipment advantage

A Cost-efficiency

● "V" groove guide device can adjust the height vertically, faster and more stable to adapt to different thickness of the substrate, increase the range of use

● The cutting knife can be turned over and reused many times to reduce the cost

B Safety design

● The stroke of the cutting plate is less than 1-2mm, and there is no concern about the operation safety

C Stability performance

● The blade parts are made of SKD11 high speed steel, wear-resistant, durable, guaranteed for one year

● Stainless steel platform with laser calibration positioning function (1.2m or 2.4m optional). There is no limit to the length of the board.

Process solution

Customer question: How many MM board can be divided into the narrowest light strip board?

Answer: The narrowest board can be less than 3.5MM, if you want to divide the aluminum base plate, it is recommended to use a double knife seat dividing machine

Customer question: machine maintenance consumables, life

A: All the products of the company include blades and accessories, 3 months warranty, the life of the cutter

The length of life is determined by several aspects, the first is the material, the imported high speed steel will be better than the ordinary

The material should be durable, secondly, the material of the cutting board will also affect the life of the tool, cutting glass fiber board

It will be more durable than cutting aluminum substrate

Customer question: light strip machine can be divided every day how many strips

A: The light strip splitter can be 12,000 to 15,000 strips per day, the speed is 400M/S, 8-10 hours

Features:

1.750 plate splitting machine adopts six groups of cutting tools to cut step by step to reduce the shear stress to the minimum, and is equipped with deformation control device, the edge of the segmented substrate is smooth and smooth, the surface is very smooth, no twisting or warping, yes

About 0.6mm ultra-thin aluminum substrate slitting can still perfectly control its deformation in two wires, meet the glass

The strict requirement of deformation degree in pipe process

2. Because of multiple cutting, the cutting process is very smooth, greatly improving the positioning ability of V-CUT slot, even if the V-CUT slot is very shallow circuit board, there will be no V-CUT slot from the guide knife jump out of the situation, to avoid defective products.

3. All cutting blades are calibrated with an excited dual-frequency laser interferometer to ensure that the rear blade can be cut in the slot of the front blade

Continue cutting exactly. Tip beat no more than 0.02mm, to ensure perfect cutting quality.

4. Stainless steel platform with laser calibration positioning function (1.2m or 2.4m optional)

Application field

The YSL-750 is used in:

750 plate machine adopts six groups of cutting tools to cut step by step, the shear stress is reduced to the minimum, and the deformation control device is configured, the edge of the segmented substrate is smooth, the surface is very flat, no twisting or warping, the ultra-thin aluminum substrate cutting about 0.6mm can still perfectly control its deformation in two wires, to meet the glass tube process on the deformation of the harsh requirements.

Because of multiple cuts, the cutting process is very smooth, greatly improve the positioning ability of V-CUT slot, even if the V-CUT slot is very shallow circuit board, there will be no V-CUT slot from the guide knife jump out of the situation, avoid bad

a. Mainly used in electronic, electrical, lighting, medical, automobile new energy, automobile and other electronic technology industries;

Defective PCB board

Machine sub-board after PCB board

Equipment parameter

| Machine specification | 490mm*400mm*350mm |

| Plat size | 1200*450*350mm/2400*450*35mm |

| Maximum splitter length | Unlimited |

| Split-plate velocity | 80, 120, 200, 400mm/s |

| Power | 60W |

| Tool material | SKD61 High speed steel |

| Plate thickness | 0.2-5mm |

| Machine weight | 1.2M—65KG;2.4M—75KG |

| Power supply | 230V/50Hz(110V/60Hz) |

Board operation procedure

value

A Cost saving

Maximum plate cutting length: unlimited, maximum plate thickness :0.2-5mm, the cutting force of the blade is small, and the use of high-speed steel materials imported from Germany, the blade durability is greatly improved, the blade life can reach more than one year when dividing the aluminum substrate. Applicable circuit plate wide range, save manpower, greatly improve the product efficiency.

B High equipment efficiency

X and Y axis can be adjusted freely to improve the cutting accuracy to the highest. The speed of the sub-board can reach 80, 120, 200, 400mm/ s. The upper and lower round knife can be adjusted accurately, simple operation, fast speed.

C Quality is guaranteed

All cutting blades are calibrated with an excited dual-frequency laser interferometer to ensure that the rear cutter can accurately continue cutting in the slot where the front cutter cut. Tip beat no more than 0.02mm, to ensure perfect cutting quality.

Equipment advantage

A Cost-efficiency

● "V" groove guide device can adjust the height vertically, faster and more stable to adapt to different thickness of the substrate, increase the range of use

● The cutting knife can be turned over and reused many times to reduce the cost

B Safety design

● The stroke of the cutting plate is less than 1-2mm, and there is no concern about the operation safety

C Stability performance

● The blade parts are made of SKD11 high speed steel, wear-resistant, durable, guaranteed for one year

● Stainless steel platform with laser calibration positioning function (1.2m or 2.4m optional). There is no limit to the length of the board.

Process solution

Customer question: How many MM board can be divided into the narrowest light strip board?

Answer: The narrowest board can be less than 3.5MM, if you want to divide the aluminum base plate, it is recommended to use a double knife seat dividing machine

Customer question: machine maintenance consumables, life

A: All the products of the company include blades and accessories, 3 months warranty, the life of the cutter

The length of life is determined by several aspects, the first is the material, the imported high speed steel will be better than the ordinary

The material should be durable, secondly, the material of the cutting board will also affect the life of the tool, cutting glass fiber board

It will be more durable than cutting aluminum substrate

Customer question: light strip machine can be divided every day how many strips

A: The light strip splitter can be 12,000 to 15,000 strips per day, the speed is 400M/S, 8-10 hours