Many companies have different PCB boards. Each customer does not have the same products. The types of PCB boards are also different. Therefore, it is better to use different boarding machines for different PCB boards, depending on the PCB board of the product. Suitable sub-board machine, many companies in the automation of the sub-board machine use the automatic sub-board machine, which increases the output of the operation, so it is good to choose the automatic sub-board machine, provided that the PCB board is suitable. The following small series introduces the three knowledge of selecting a sub-board machine.

There is also a PCB board with components, the components are not very high, and the board is not large, you can use the Yushun YSV-3A--PCB automatic knife-type splitter. The versatility of this slab is very strong. After connecting multiple plates to the solder, it will often damage the line or break the electronic parts when broken. This machine can be divided by the knife to completely reduce stress and prevent solder joints. Cracking and part breakage, improve production efficiency and quality; adopt the upper knife under the flat knife method, the plate is on the lower flat knife, the switch is stepped on, the upper circular knife moves laterally to the set fixed point, that is, the PCB board is cut and divided, cut off No peeling, the cut is flat, no burrs. A conveyor platform can also be added to facilitate the automatic delivery of the cut PCB board.

The smaller, thinner, and simpler PCB board is recommended to be cut with a boring machine. The boring-type slating machine adopts the latest gas-electric lightweight design to complete the shear-free shearing stroke at one time, especially suitable for cutting precision SMD or thin plate; the bow wave (BOW WAVES) and micro generated when there is no round knife type slab MICRO CRACK, using a wedge tool linear splitter, minimizes shear stress, leaving sensitive SMD components and even capacitors unaffected, minimizing potential product quality risks.

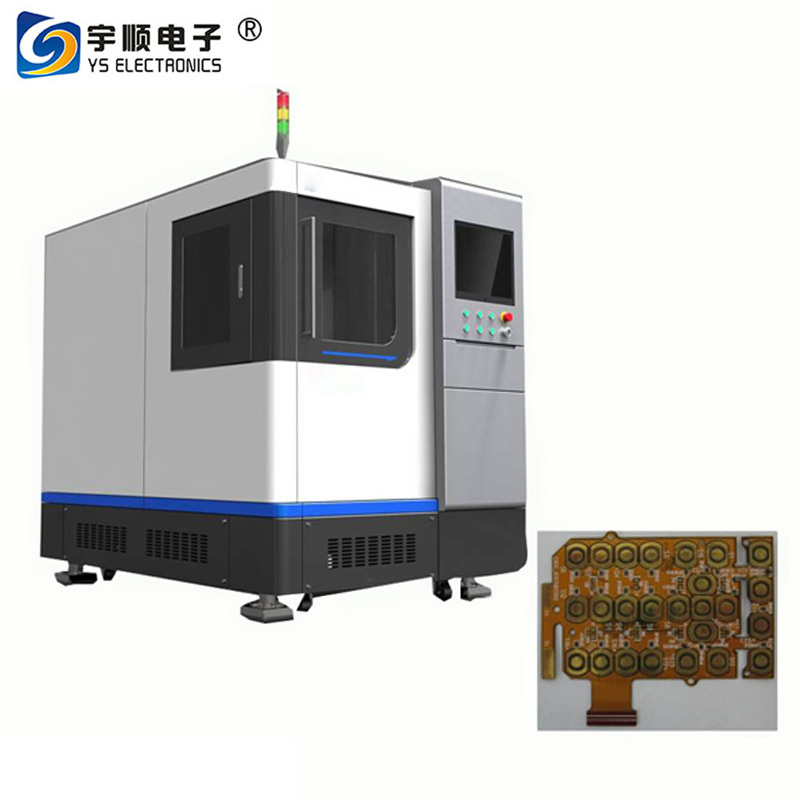

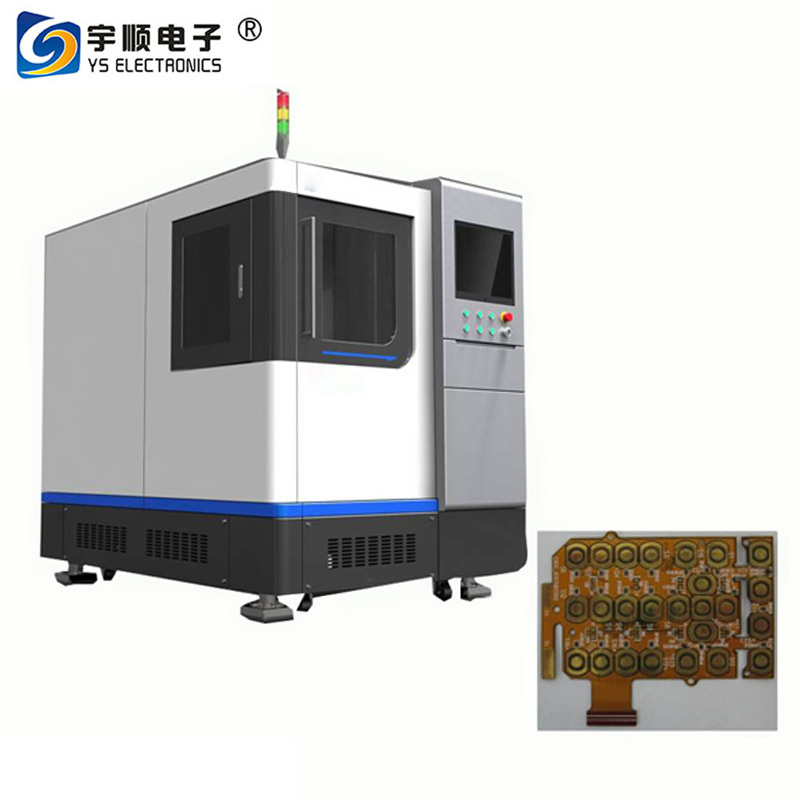

For those irregular PCB boards, stamp plates, and dot plates, a PCB milling cutter can be used.

This kind of splitting machine mainly uses the high-speed operation of the milling cutter to divide the multi-piece PCB according to the pre-programmed path, instead of the manual breaking or V-CUT or PUSH cutting boring, the cutting precision is high and accurate, and the service life is long. Good cutting quality, no dust, no burrs, low stress, safe and simple, improve product quality and reduce scrap rate. Mainly used to divide irregular PCB boards, stamp plates, and even points. The cutting stress is smaller, about 1/10 of the stamping type and 1/100 of the handcuff, thereby preventing the chip such as ceramic capacitor from being damaged during the cutting process; avoiding the problem of cracking of the tin and damage of the component caused by the artificial folding plate.

Many companies have different PCB boards. Each customer does not have the same products. The types of PCB boards are also different. Therefore, it is better to use different boarding machines for different PCB boards, depending on the PCB board of the product. Suitable sub-board machine, many companies in the automation of the sub-board machine use the automatic sub-board machine, which increases the output of the operation, so it is good to choose the automatic sub-board machine, provided that the PCB board is suitable. The following small series introduces the three knowledge of selecting a sub-board machine.

There is also a PCB board with components, the components are not very high, and the board is not large, you can use the Yushun YSV-3A--PCB automatic knife-type splitter. The versatility of this slab is very strong. After connecting multiple plates to the solder, it will often damage the line or break the electronic parts when broken. This machine can be divided by the knife to completely reduce stress and prevent solder joints. Cracking and part breakage, improve production efficiency and quality; adopt the upper knife under the flat knife method, the plate is on the lower flat knife, the switch is stepped on, the upper circular knife moves laterally to the set fixed point, that is, the PCB board is cut and divided, cut off No peeling, the cut is flat, no burrs. A conveyor platform can also be added to facilitate the automatic delivery of the cut PCB board.

The smaller, thinner, and simpler PCB board is recommended to be cut with a boring machine. The boring-type slating machine adopts the latest gas-electric lightweight design to complete the shear-free shearing stroke at one time, especially suitable for cutting precision SMD or thin plate; the bow wave (BOW WAVES) and micro generated when there is no round knife type slab MICRO CRACK, using a wedge tool linear splitter, minimizes shear stress, leaving sensitive SMD components and even capacitors unaffected, minimizing potential product quality risks.

For those irregular PCB boards, stamp plates, and dot plates, a PCB milling cutter can be used.

This kind of splitting machine mainly uses the high-speed operation of the milling cutter to divide the multi-piece PCB according to the pre-programmed path, instead of the manual breaking or V-CUT or PUSH cutting boring, the cutting precision is high and accurate, and the service life is long. Good cutting quality, no dust, no burrs, low stress, safe and simple, improve product quality and reduce scrap rate. Mainly used to divide irregular PCB boards, stamp plates, and even points. The cutting stress is smaller, about 1/10 of the stamping type and 1/100 of the handcuff, thereby preventing the chip such as ceramic capacitor from being damaged during the cutting process; avoiding the problem of cracking of the tin and damage of the component caused by the artificial folding plate.