PCB sorting machine types, advantages and disadvantages

The PCB board machine is also called a circuit board board machine and is widely used in the electronics manufacturing industry. The early splitting machines used manual manual splitting, which had low efficiency and great damage to the substrate. Some of the boards even had components inserted, so the mechanization was eliminated and the processing method was eliminated.

With the advancement of technology, the way of PCB sub-boarding is becoming more intelligent, efficient, and accurate. Of course, the cost is also increasing, and the needs and requirements of customers are also increasing. How can it stand out in the demand of modern production? For PCB board processing companies, it is imperative to keep pace with the times.

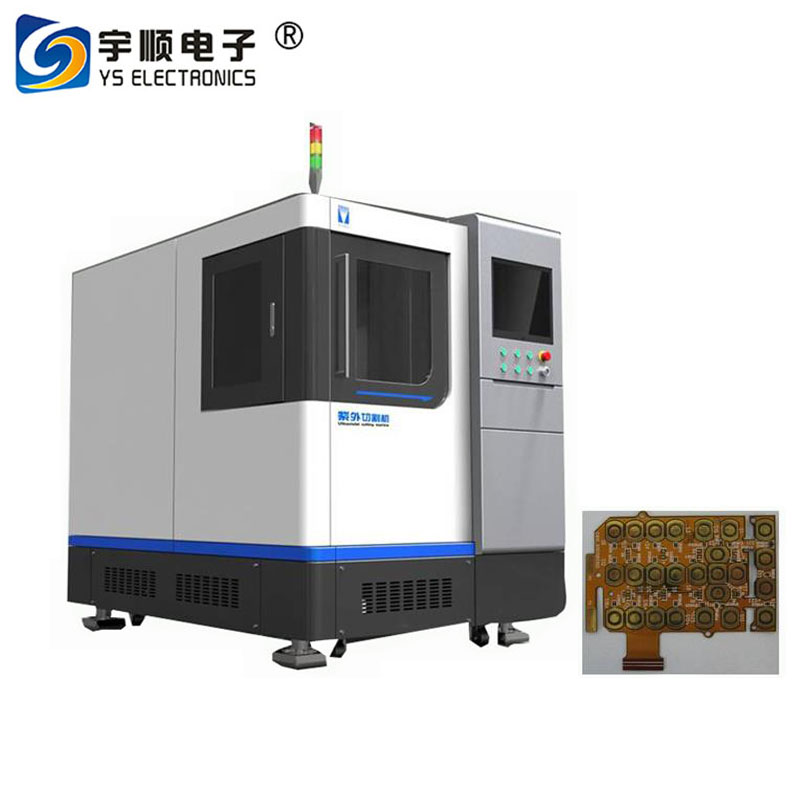

Laser splitting machine is an emerging technology. With the development of laser technology, the application of laser technology in the field of electronic manufacturing is more and more, and it is one of the applications in PCB sub-board. Different lasers are used according to requirements. Currently, there are ultraviolet lasers, CO2 lasers, green lasers and picosecond lasers, and the natural price is very different. In terms of overall cost performance, the current mainstream is the use of ultraviolet lasers and green lasers.

The thickness of the UV laser cutting machine on the PCB sub-board is low, generally not more than 1mm, the green light is mainly high power, and the laser sub-board is applied to the PCB above 1mm.

The biggest part of the laser splitter is the cutting efficiency and cutting effect. The edges of the cut are carbon-free and burr-free. And there is adsorption function, which makes it dust-free and smoke-free. The laser uses a non-contact processing method, which has a small thermal influence and does not damage the substrate or the substrate of the active device without stress. The CCD positioning is used, the computer controls the automatic cutting, and the function of automatic loading and unloading can also be realized. Maximize equipment productivity and labor costs.

Of course, the shortcomings of the laser splitter are also very obvious, and the price is high. The price of the UV laser PCB splitter is in the range of 40-800,000 in September 2016 (depending on the accessories and laser power). The cost is very high.

The defects of the equipment such as the curve splitter, the knife splitter, the boring splitter, the punch splitter, the pusher splitter, and the mill splitter are the defects of the PCB splitter. All are in contact with the processing method, which will cause stress and damage the substrate. There are burrs on the edges of the cut and a large amount of dust is generated, which is not conducive to the development of sustainability and environmental protection.

Of course, the input costs of these models are relatively low. But in general, it needs to be determined according to its own needs, which equipment is the most ideal. For example, if your processing volume is only to meet your own small production needs, then there is no need to buy high-quality equipment, you can spend more time slowly by hand-pushing the splitting machine, but if there is high quality Demand and mass production, laser splitters may also be a good choice.